Recycling & Repurposing Ribbons - The Way Forward...

Over the last few decades ribbons moved away from being manufactured in natural fibre to being spun in polyester, which with hindsight was a very enviromentally, unfriendly move...which it was!

This was sadly in the day when saving the environment was not at the top of anyone's agenda. However the good news is that todays world is changing fast, with many firms re-evaluating their position and starting to look carefully at their enviromental footprint. Whilst cost is still an important factor for a lot of buyers, it's no longer the end of the story, and thus enables the spinners to change the parabellum.

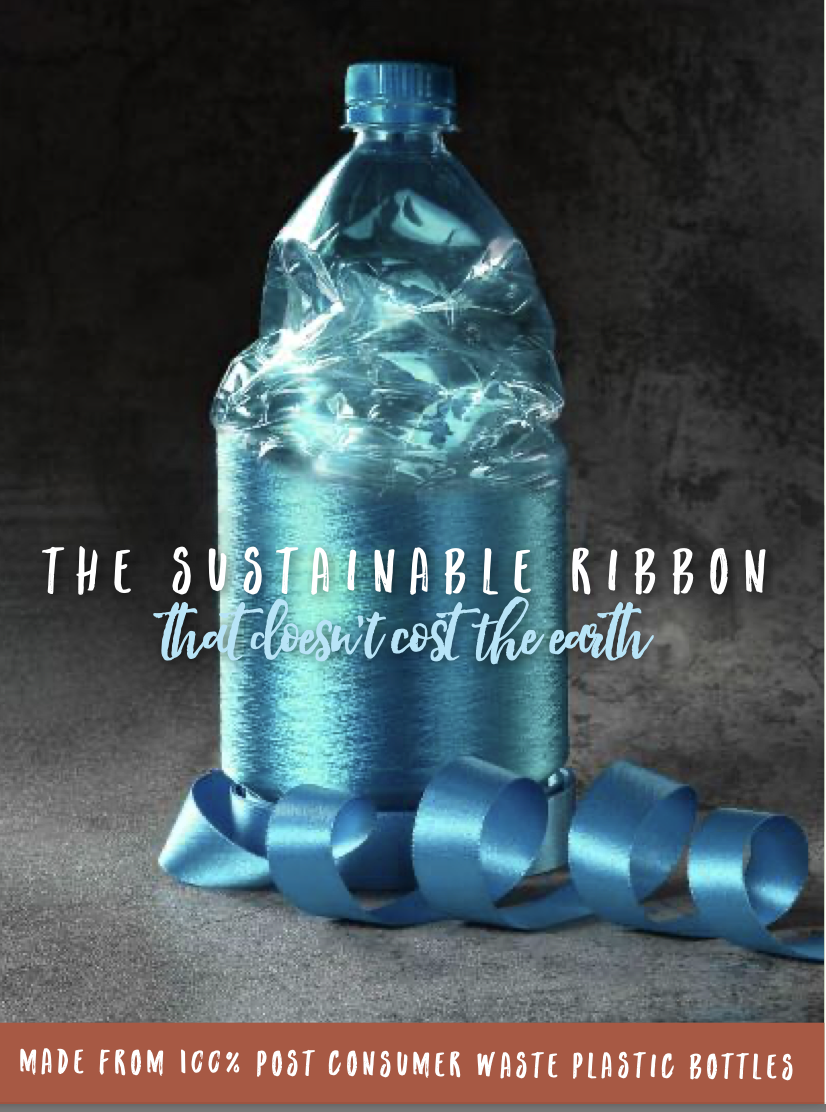

Ribbon spinners today are now trying to address the need to provide ribbon solutions that literaly do not cost the earth!

As a wholesaler we have an important part to play in this move and with this in mind, we are working with partner spinners who can offer true solutions to these issues.

Our UK Manufacturer Berisfords Solution.

As the last major UK Ribbon manufacturer, Berisfords have looked hard at their use of man made fibres and have also assessed the impact of changing to natural fibre for making ribbons.

Unfortunately this is not as simple a solution as it may appear. For example 1kg of cotton takes over 10,000ltrs of water to produce. This is a massive quanitity and in it's self is a very unenviromental process. In addition cotton is one of the most pesticide intensive crops in the world with more chemicals used in the production of cotton then any other crop!

The alternative that Berisfords came up with was to use recycled polyester which comes from plastic drink bottles!

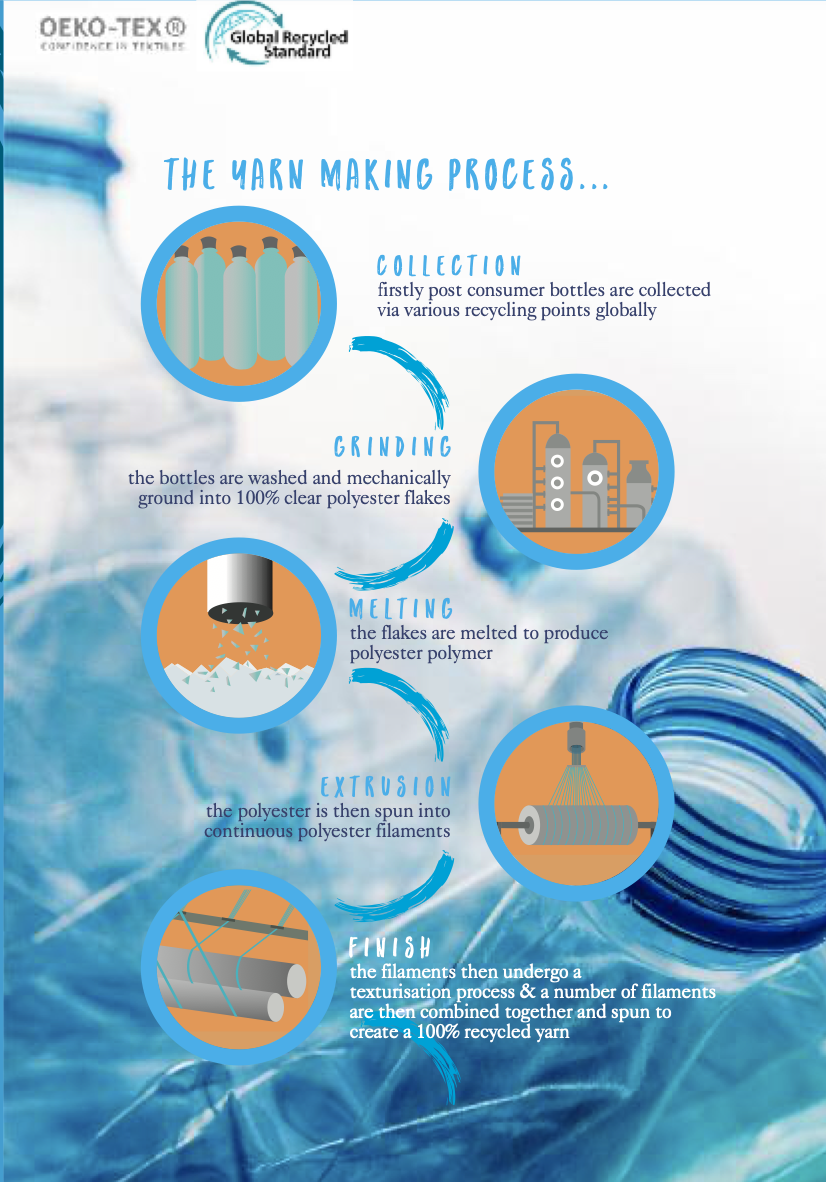

So how does this work and how do you turn plastic drinks bottles into polyester ribbon?

The first stage is to collect the used bottles from various recycling plants globally. These bottles are then washed and ground down machanically to become100% polyester flakes. The flakes are then melted to make polyester polymer. Once in a polymer format, this is then extruded and spun to make polyester filerment. The filerment then undergoes a texturisation process and a number of filerments are combined together and spun to form a 100% reycled polyester yarn.

These yarns can then be taken and woven in to ribbons.

But keeping it all environmentally friendly doesn't end there, as the finished ribbon has to be wound on to a reel which in it's self leads to another challenge. Traditionally the flanges and core are made from clear virgin plastic, however Berisfords have again managed to address this with two alternatives...to use plastic from recycled household white goods to make the white plastic reels that you see the ribbon on today, and the cardboard reel centres on the bulk and retail reels being made from recycled card which in turn can be recycled again.

The last part of the ribbon manufacturing to address is the cellophane covering that is used to protect the surface of the ribbon. This is also now made from a product that is bio degradable.

This makes the whole ribbon process from start to finish, including the packaging, enviromentally responsible and is a massive step forward!

From 2021 onwards Berisfords Ribbon are converting their Ribbon production to utilise these "New Life" yarns across their whole ribbon ranges. This process will take a while to complete, however they are already making and expanding the range of double satin ribbon using the new yarns, of which we are currently stocking the complete range and will continue to do so with each product they launch on this basis in the future.

Berisfords are just one of our suppliers who are taking a very proactive approach to these plastic ribbon issues, whilst maintaining a very high quality level of product. Other manufacturers such as the German firm Halbach have also made huge inroads into sustainable products, which we will write about in our next Blog.

We hope you find this information helpful.

Facebook

Facebook Twitter

Twitter Pinterest

Pinterest